Why choose the Mastersizer 3000?

The Mastersizer range has been trusted by scientists for generations. And the 3000 range has been developed with a deep understanding of real-world use, resulting in the most advanced and user-friendly particle analyser in the world.

What makes this model special?

-

Measures a large sample size range

Incredibly versatile, the 3000 accurately measures particles (from 10nm up to 3.5mm). -

Switches easily between wet and dry dispersions

The ergonomic, easy-to-use hoppers make it easy to load liquids and powders, switch between the two, and prep and clean quickly. -

Data how you want it, with customisable reporting

Flexible reporting means you get your data how you need it, and can integrate them simply and seamlessly into your workflows. -

Intuitive software with ‘built-in expertise’

The easy-to-use software also proactively monitors your data quality, flagging potential issues (such as insufficient sample size, or if the instrument needs cleaning) -

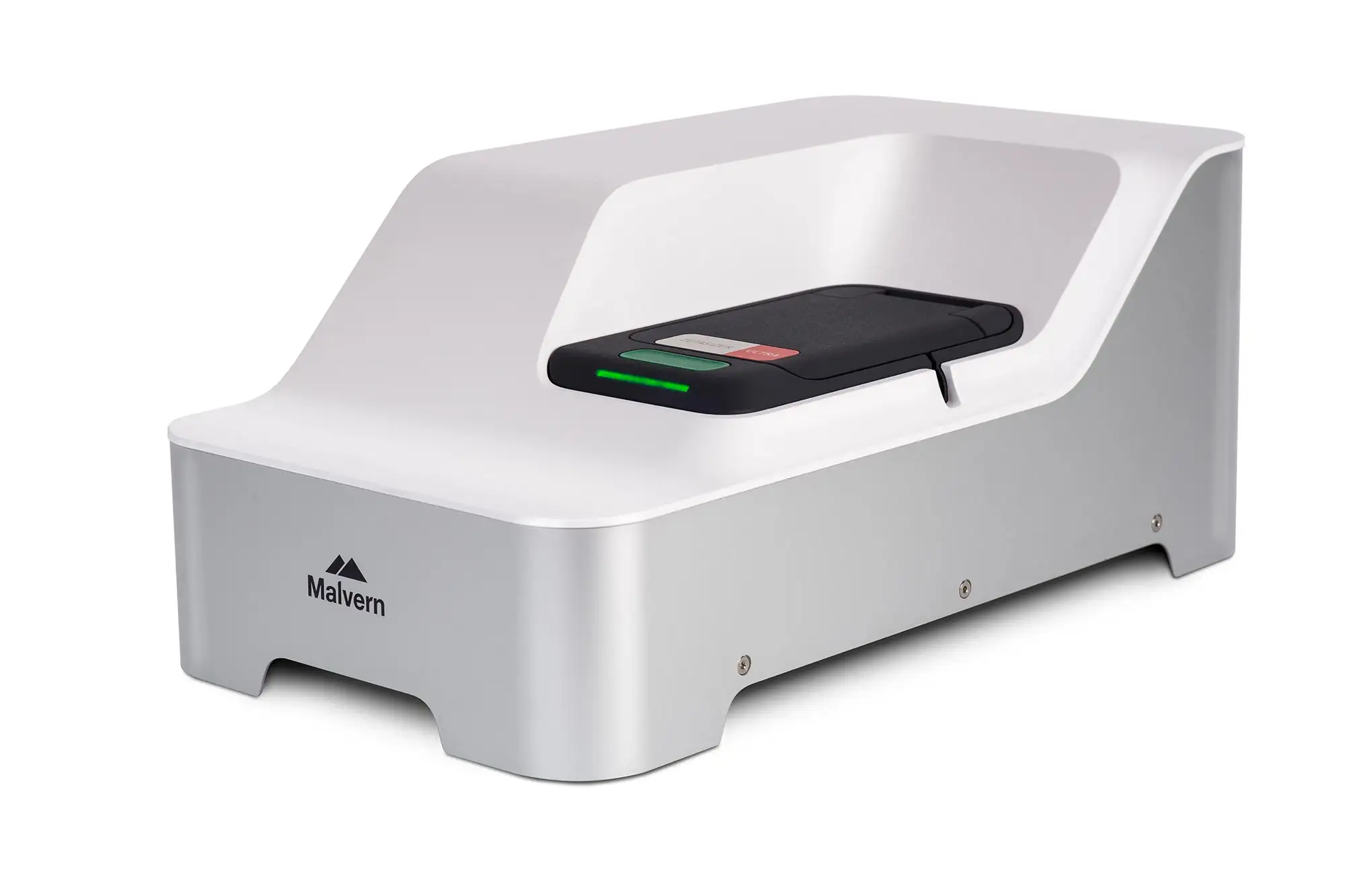

Compact. Well designed. Easy to use.

The 3000 has been ergonomically designed to be as space-saving as possible and simple to load, use, clean and service.

Malvern Panalytical’s unique, practical laser diffraction particle size analysis know-how enables the Mastersizer to deliver results you can rely on, with data quality analysis that empowers both particle sizing experts and measurement novices to deliver insight and results you can trust. For the Mastersizer 3000 price, please click to request a quote.

Data generated on the instrument is very reliable and accurate. Method development on the instrument is very simple and gives reproducible results time and again...

Tyrone T. – Oil processing

Read what our customers think of the Mastersizer 3000 system

Understanding your Mastersizer 3000

Particles are too small to measure directly – but by firing a laser beam at a sample and measuring the intensity of the light that gets ‘scattered’, we can accurately calculate a particle’s size. The Mastersizer 3000 is the world’s fastest, most accurate and most reliable instrument for doing this.

There are three key components: the optical bench that houses the laser and sensors; the sample dispersion units where you load samples for analysis; and the user-friendly software that helps you run, report and interpret your data.

-

Optical bench and laser

This is the heart of the Mastersizer, housing the laser and detectors which measure particles from 10nm to 3.5mm. It uses both red and blue light and captures measurements across a wide range of angles. -

Sample dispersion units

The dispersion units deliver samples consistently and in the correct concentration. There are six wet dispersion units to handle the widest possible range of sample volumes and dispersants, and a dry dispersant system that handles rapid powder dispersion, even for fragile materials. -

Intuitive software with ‘built-in expertise’

The dispersion units deliver samples consistently and in the correct concentration. There are six wet dispersion units to handle the widest possible range of sample volumes and dispersants, and a dry dispersant system that handles rapid powder dispersion, even for fragile materials.

Frequently asked questions

- Do I need to prepare the workspace prior to installation?

- All instruments need a power source, and some have additional requirements such as a water supply or waste extraction. Where this the case, we will advise you prior to shipping your instrument.

- What specialist skills or knowledge are required?

- You don't need any specialist skills or knowledge to perform a Smart Install. Simply follow the instructions provided.

- Do I need specialist tools or equipment to Smart Install a new instrument?

- For installation of a Mastersizer or Zetasizer system, you will need a computer with internet access in order to view the installation guides. For installation of an Epsilon 1 XRF instrument, you will also need a smartphone or tablet to connect with our support personnel via a secure, augmented reality (AR) platform.

- Everything else you need to install your new instrument will be provided.

- What languages are available for the Smart Install guides?

- Mastersizer: English, Chinese, Korean, French, German and Japanese

- Zetasizer: English, Chinese, Korean, French, German and Japanese

- Epsilon 1: English, French, German and Japanese, Spanish and Portuguese

What customers use the Mastersizer 3000 for

The Mastersizer 3000 lets users find the particle size ‘sweet spot’ for a vast array of processes – helping them create substances that behave more predictably, more safely and to a higher quality. Mastersizers are frequently used for:

-

Creating smooth-flowing powders

Many manufacturing processes need powders to flow smoothly. (Too small and flow is unpredictable; too large and the density of final products can be affected). It’s important for processes such as ‘additive’ manufacturing (like 3D-printing), and controlling the quality of sintered products. -

Packing powders to the right density

The way particles pack together depends on both their size, and the mix of differently-sized particles. Getting the balance right means denser packing. It’s essential for mould-based manufacturing (eg ceramic and metal components) as well as for processes such as powder coating. -

Mixing stable dispersions

Getting the particle sizes ‘just right’ in dispersions is the difference between creating a stable dispersion with evenly distributed particles, or one with agglomerations. (That’s the difference between an even powder coating or smooth-flowing paint, or dispersions with lumps in.) -

Dissolving substances predictably

Particle size directly affects the speed at which a substance dissolves. (Smaller is faster; larger is slower). This is particularly critical in the pharmaceutical industry, where this affects the release rate of the active components of a drug. -

Controlling how particles are inhaled

Particle size affects how easy it is for people to inhale substances. In both medicine and industry there are strict guidelines for particle sizes – broadly speaking, so that drugs are quickly and easily inhaled, and harmful substances (such as cleaning products and hairsprays) are not. -

Deciding chemical reaction times

Particle size determines volume-to-surface-area ratios, which affects chemical reaction times. Controlling reaction times is important in manufacturing processes such as the hardening of cement, and in producing effective catalysts (such as cleaning pollutants from medicines.) -

Manipulating how light reacts with substances

The particle sizes in pigments, paints and coatings affects how the final products scatter light. So by controlling the particle size, manufacturers can control how bright, strong or glossy something looks. -

Improving the quality of food and drink

The particle sizes in food and drink can have a dramatic effect on how they smell, taste and feel: the particle size of ground coffee affects its strength and brew time; smaller particles in chocolate give it a silkier mouth-feel and better quality.

Specifications

General

| Particle size | Suspensions, emulsions, dry powders |

|---|---|

| Principle | Laser light scattering |

| Analysis | Mie and Fraunhofer scattering |

| Data acquisition rate | 10 kHz |

| Typical measurement time | <10 sec |

| Dimensions (W, D, H) | 690mm x 300mm x 450mm |

| Weight | 30kg |

Optics

| Red light source | Max. 4mW He-Ne, 632.8nm |

|---|---|

| Blue light source | Max. 10mW LED, 470nm |

| Lens arrangement | Reverse Fourier (convergent beam) |

| Effective focal length | 300mm |

Detector

| Arrangement | Log-spaced array |

|---|---|

| Angular range | 0.015 - 144 degrees |

| Alignment | Automatic |

Size

| Particle size | 0.01 – 3500 µm * |

|---|---|

| Accuracy | Better than 0.6% ** |

| Number of size classes | 100 (user adjustable) |

| Precision / Repeatability | Better than 0.5% variation ** |

| Reproducibility | Better than 1% variation * |

Software

| 21 CFR part 11 | Enables an operating mode that assists with ER/ES compliance |

|---|

System compliance

| Laser safety | Class 1, IEC60825-1:2007 and CFR Chapter I: Sub-chapterJ: Part 1040 (CDRH) |

|---|---|

| Regulatory testing | RoHS and WEEE compliant CE / FCC compliant Meets requirements of the European Low Voltage directive |

System

| Power | 100/240 v, 50/60 Hz 50W (no dispersion units connected) 200W maximum (2 dispersion units connected) |

|---|---|

| Humidity | 80% maximum for temperatures up to 31°C, decreasing linearly to 50% at 40°C. Non condensing. |

| Operating temperature | +5°C to +40°C |

| Product storage temperature | -20°C to +50°C |

| Ingress Protection (IP) rating | IP41B |

Notes

| * | Sample and sample preparation dependent. |

|---|---|

| ** | Accuracy defined for the measurement of monomodal latex standards. This specification accounts for the manufacturer’s uncertainty in the latex size. Sample and sample preparation dependant. |

| Patents | The Mastersizer 3000 optical bench is protected by patents; US6,778,271 and related filings; GB2,340,932; together with patents based on applications WO2013038161, WO2013038160 and WO2013038159. Hydro MV and LV protected by EP1167946A2 and related filings. |

Accessories

Sample dispersion accessories for the Mastersizer 3000.

Hydro MV

Medium volume automated dispersion unit

The Hydro MV is a medium volume unit for the controlled, automated wet dispersion of samples for particle size analysis. Suitable for both aqueous and non-aqueous applications, it is especially useful when sample size is limited and/or dispersant use must be minimized.

Mastersizer 3000 Chocosizer

Effective Chocolate production quality control

The Mastersizer 3000 Chocosizer is designed to support chocolate production and quality control by providing a simple method for fast, reliable chocolate particle size analysis.

Support

Protect your investment and ensure optimized performance at all times with Malvern Panalytical's service plans.

When you purchase a Malvern Panalytical product we understand that this is just the first stage of a working relationship that will last for the lifetime of the instrument. Depending on your needs, Malvern Panalytical will provide the support for your business.

We offer the following service options:

Platinum Plan

For laboratories where maximizing instrument up-time is critical to its daily performance. Our highest level of response and the 'all inclusive' price plan takes care of those unexpected repair bills should the unfortunate occur.

Gold Plan

Enhance your laboratory productivity by maintaining instrument efficiency. Priority response combined with specialist technical and software support. We'll keep your instrument performance on track to deliver.

Bronze visit

For laboratories looking to optimize instrument performance, regular preventative maintenance is essential.

| Platinum plan | Gold plan | Bronze visit | |

|---|---|---|---|

| Annual PM / PV test | |||

| Telephone / email support | |||

| Priority response | |||

| Emergency breakdown visits* | |||

| Parts included | |||

| Technical and software support | |||

| IQ / OQ (pharma)** |